On behalf of our customers, we design, evaluate and optimize both complete thermal systems and individual system components. In doing so, we make use of various simulation methods, some of which we have developed and tested many times over. Our expertise covers the following areas of application, among others:

Simulation

Stationary Refrigeration and Heat Pumps

We model and simulate both heat pumps and stationary refrigeration systems in all performance classes for our customers: from small household appliances such as refrigerators, to household heat pumps, refrigeration systems for supermarkets or hydrogen filling stations, and large heat pumps for supplying heat to entire residential areas. Our focus is on the design, analysis, and optimization of these systems.

Mobile Air Conditioning and Thermal Management

On behalf of our customers we design, evaluate, and optimize thermal components and systems of electric vehicles. In addition to efficient operating strategies and heating and cooling of the interior, we also focus on the intelligent integration of powertrain components as thermal sources and sinks. For the analysis of the holistic thermal management system, we include measurement data from real driving. Increasing energy efficiency and driving range is the focus of our work.

Batteries

We answer our customers' thermal inquiries into battery cells, modules, and systems. Thermal management and aging, as well as safety are in focus. In particular, we deal with lithium-ion batteries in battery electric vehicles and in stationary battery storage systems.

Hydrogen

We develop and optimize components and systems for the production, storage, and distribution, as well as for the energetic and material transformation of hydrogen. From electrolysis to compressed gas systems, cryogenic tank systems, and filling stations, to fuel cell systems (including hydrogen conditioning in vehicles and aircraft), we consider numerous systems along the value chain.

Process Engineering

On behalf of our customers, we design and optimize various process engineering systems. Here, we benefit from our many years of experience with dynamic modeling and simulation - for example, for power plants, wastewater treatment plants, direct air carbon capture (DAC), or drying processes.

Control Engineering

We support our customers in the design and analysis of control systems, as well as designing controllers and testing them with xiL methods, for example PID control loops, multivariable controllers with gain scheduling, or model-based predictive controllers.

0D/1D-Methods

The modeling approaches we use at TLK to represent thermal systems and their components are based either on highly detailed CFD simulations, on fast data-driven calculations, or on physically motivated 0D/1D methods. In 0D/1D methods, components are averaged over the location (0D) or discretized over the location resolved one-dimensionally (1D). The level of detail depends on the respective requirements and questions of our customers.

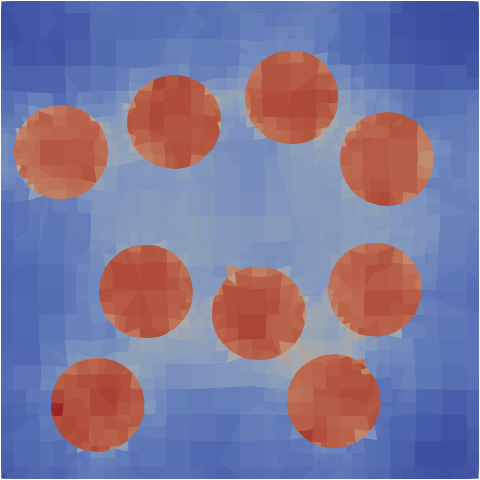

CFD and Field Calculation

On behalf of our customers, we map physical relationships with highly discretized field computation and CFD methods. In pre-processing we prepare geometries and mesh them. We select suitable modeling and solution methods, perform parallelized calculations, and visualize the results in a meaningful way. If required, we automate these steps and perform model reductions.

Machine Learning

We create real-time capable data based models of components and systems for our customers, which can be used, for example, in complete system simulation or for control development. The models we develop are based on simple polynomial approaches, methods of Proper Orthogonal Decomposition (POD), neural networks, or combined physical and data based model approaches.

Automation in Simulation

The simulation of components and systems contains many repetitive steps that take up a significant part of the development time of a product. These include, for example, the analysis and visualization of simulation results and the optimization of parameters. To support these processes and thus shorten development times, we offer our customers individually tailored automation of the corresponding workflows.